Proper preparation is the key to laying a slab that lasts. In this article, we step through the essential steps to ensure a smooth and strong foundation from start to finish.

As the director of OMNI Built Homes with over 30 years of experience in the project home and custom home building industry, I have overseen numerous successful projects from conception to completion.

A common misconception I come across is that many people think a home begins with laying the slab. But the truth is that there are at least five essential steps behind the scenes that set up the whole build for success.

More time and effort often go into the preparation than the pour itself. In fact, the slab pour is sometimes the easiest part of the entire process!

When preparing to lay a slab, here are five things you need to tick off before any concrete is poured:

Finalise the design and floor plans

Before work even begins, everything needs to be mapped out down to the detail. Many people believe they can lay the slab, understand the dimensions, and everything will fall into place as they go. But you need to be completely happy with the positioning, orientation and layout of your home long before the concrete arrives.

By the time we’re ready to pour, the design should be firmly locked in. You don’t want to realise too late that you’d prefer an extra room, or that the living space would work better slightly to the left to capture more natural light. That kind of change can quickly become one of the most expensive decisions you’ll ever make.

Plan the slab with the right engineering support

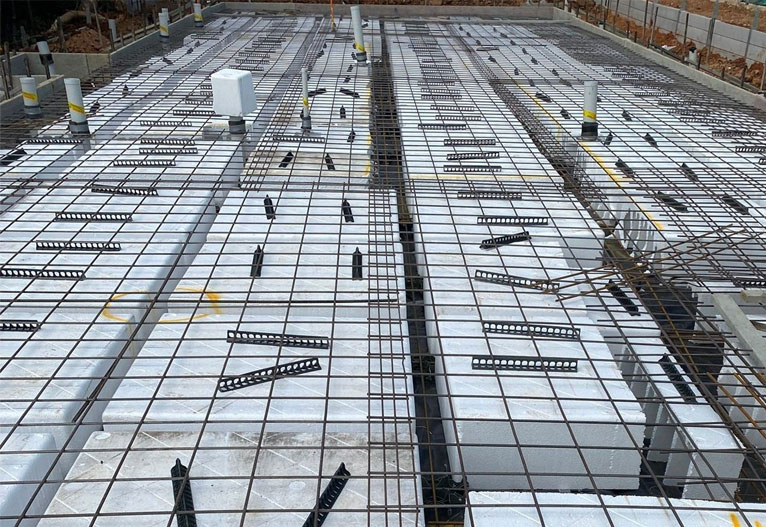

You’d be surprised how many people think a slab is just concrete and steel. The truth is, there’s a lot of planning that goes into it. Before we pour anything, we work with engineers to figure out how thick it needs to be, how much steel it needs, and how it reacts with the soil underneath.

Every block is different. Some soils move a lot, while others barely shift, which impacts everything from the slab type to how deep we dig. If we get this wrong, it impacts the whole build, so it’s a step that we can’t cut corners on. We’ve learnt how important it is to allocate the right amount of time to get it right, and the budget to hire the right people to do it. Without the right engineering, the slab may as well not even be poured.

Sort out building approvals and safety compliance

Now, this might not be the most exciting part of the build, but it has to be done right from the start. Securing building approval isn’t just for safety; it’s a legal requirement. Depending on where you’re building, starting construction without approval can result in fines of over $75,000 and bring the entire construction to a standstill.

This is also the time we get the fencing and signage sorted to make sure the site is safe and compliant. Getting all the paperwork, approvals and safety measures sorted early sets us up for a smooth, stress-free build from the very beginning.

Prepare the site, even if it’s a new block of land

A slab is only as good as the ground it’s poured on. That’s why site preparation is a non-negotiable step in the process. Just because you’ve bought the land doesn’t mean it’s build-ready, and most people don’t realise this.

We make sure the site is cleared, levelled, and properly compacted. If it’s a flat block, this can be super simple, but for sloped or split-level homes, it takes more planning to get right. This step also includes removing any existing structures, pathways, gardens or debris to prepare the land for the equipment needed for the build.

Map out your drains and rough-ins

Once that concrete is down, there’s no going back (or it will cost you an arm and a leg!), which is why all under-slab plumbing and electrical needs have to be installed before laying a slab. This includes drainage for bathrooms, kitchens, laundries, and even electrical conduits for things like kitchen islands or future power points. Get rough-ins finalised and right the first time, because fixing mistakes after the fact usually means cutting into brand-new concrete.

After years of working on all kinds of builds, the main thing we’ve learnt is that the jobs that run the smoothest are always the ones with the right prep. These steps help us stay ahead, avoid unnecessary setbacks, keep the project on track, both in terms of time and budget and keep our clients happy!

Ever watched a slab go down? What part of the process surprised you most?

-

-

-

MH513363, QLD

- 31 Aug 2025

-

-

-

MH513900, NSW

- 30 Aug 2025

-

-

-

TraceyGail, NSW

- 28 Aug 2025

-

-

-

sars_angelchik, TAS

- 26 Aug 2025

-

-

-

MH514138, WA

- 22 Aug 2025

-

-

-

ChiWren, QLD

- 16 Aug 2025

-

-

-

MH513363, QLD

- 16 Aug 2025

-

-

-

MH514261, NSW

- 15 Aug 2025

-

-

-

El63, QLD

- 14 Aug 2025

-

-

-

MH514303, VIC

- 13 Aug 2025

-

-

-

MH513376, WA

- 12 Aug 2025

-

-

-

MH516778, QLD

- 12 Aug 2025

-

-

-

misha, VIC

- 11 Aug 2025

Post a commentTo post a review/comment please join us or login so we can allocate your points.